CO2 laser cutting systems are able to cut variety of thin metal and non-metal materials of wood, MDF, plywood, chipboard, acrylic, plastic, PMMA, leather, fabric, cardboard, paper, rubber, depron foam, woodleather, wood paper, EPM, gator foam, polyester (PES), polyethylene (PE), polyurethane (PUR), neoprene, textile, bamboo, ivory, carbon fibers, beryllium oxide, polyvinyl chloride (PVC), polyvinyl butyrale (PVB), polytetrafluoroethylenes (PTFE / Teflon), phenolic or epoxy resins, and any materials with halogens (fluorine, astatine, iodine, chlorine, bromine).

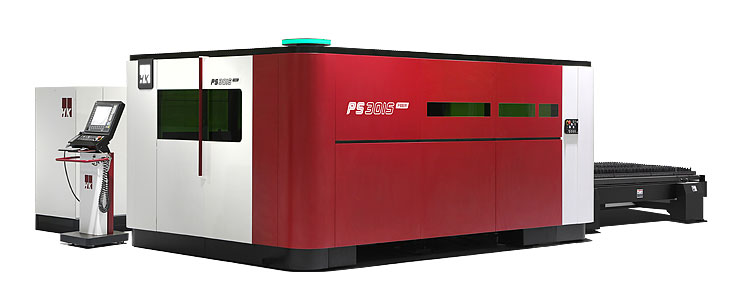

All-in-one sheet metal and tube laser cutters for sale from $42,500 to $116,000 for dual-purpose commercial use with automotion.